N-series

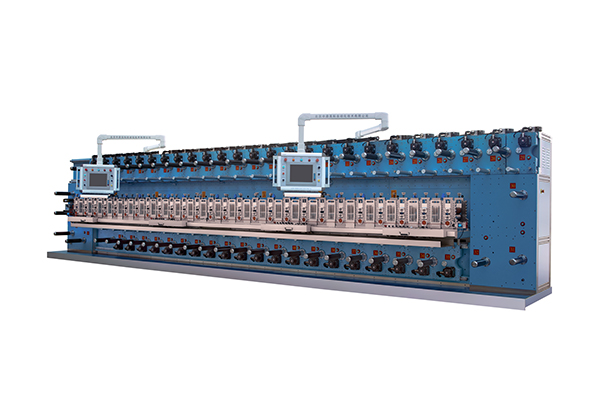

N-series 26 Stations Rotary Die Cutting Machine

Performance Characteristics

Special die cutting controller with exclusive proprietary intellectual property rights, adopts the most advanced 64 bits quad-core ARM+DSP processor, multi CPU parallel operation control and clock synchronization technology, auto tuning coupling technology with multiaxial crossing, to avoid effects on control precision by serial communication queue delay. The control cycle of 64 axis can reach 500μS.

Supports 256 channel high-speed interface, fits self-developed visual control system to realize on-line testing and message feedback of multigroup visual information.

An instruction library of die cutting functions, quickly responds to customization and development of special functions.

1. Operating system: Double fifteen-inch touch HMI panel on swing arm with separate rail mounted consoles for easy operator access.

2. Self-developed control system, function customization can be realized.

3. Synchronous control system for die cutting with short synchronous period and quick response.

4. With the function of storing all process parameters for each product, and flexible call.

5. Maximum cutting speed of 60 meters/min.

6. Maximum material width of 250 mm.

7. Each set of die cutting station is controlled by certain servo drive for start, stop, forward, reverse, synchro, scale, Fine tunning functions.

8. Each set of material shafts is driven by a separate servo system, which is used for receiving, discharging, changing direction, and anthropomorphic start-up.

9. With rectification function: automatically adjust the Y direction of the main feed axis.

10. The die-cutting tool speed can be easily adjusted independently.

11. The chip and meter alarm stop function can automatically control the device to stop according to the set quantity..

12. Each receiving and discharging axis can select automatic constant tension control or constant torque control mode respectively..

13. Island placement modules available, registered dispensing of smaller die cut components onto other components, or pre-printed web features, minimizes material waste.

14. Each of the retractable material shafts is equipped with a one-button start/stop button, which is more convenient for the operator to refuel the operation.

15. With asynchronous function: realize small piece patching, multi-piece group cutting, effectively saving cost

16. Dual process capability: run two jobs at once, any combination of stations, unwinds and rewinds. Satisfy the requirements of complex products.

17. With automatic registration function: it can automatically register according to the set size, and the positioning is accurate;

18. With fixed length cutting function: it can realize free fixed-point cutting, product spacing, avoiding sheet breakage, etc.; improve material utilization and reduce cost;

19. Batch recording function

20. Alternate cutting of AB knives

21. Z-CAM function

22. Tracking function

23. Alarm system for preset coil diameter

24. Static eliminator, reduces danger of shock and minimizes web debris.(Optional)

25. With safety protection function: it can automatically stop running in the dangerous area of the equipment, and protect personal safety to the greatest extent; (optional).(Optional)

26. CCD automatic detection registration function: CCD to adjust part position or check part position for improving product qualification rate and realizing efficient automation. (Optional)

27. standard waste function of application code printer with CCD(optional)

28. sliding operation box(optional)

Fits with self-developed CMS management system (optional)

Alarm system for wireless digital die pressure (optional)

Voice alarm system (optional)

External signal pause function (optional)

Alarm system for low pressure (optional)

Manual adjustment system for Y axis feeding shaft (optional)

Auto adjustment system for Y axis feeding shaft (optional)

Collecting and stacking system (optional)